Organomolybdenum components, such as molybdenum dialkyldithiophosphate and molybdenum dialkyldithiocarbamate , had been first introduced in the Nineteen Fifties . They decompose on rubbing surfaces to kind skinny lamellar MoS2 films, which might significantly scale back friction. Initial tests with polymer-coated plain bearings underneath cease-start conditions and boundary lubrication situations have shown very promising results.

In this case, nonetheless, dissolved molecular oxygen or peroxides have to be eliminated from the liquid section to forestall pure MoS2 sheets from being oxidized where they’re in-situ fashioned. Carbon might be more difficult to avoid, however this can be done in the near future by deciding on particular multifunction additives and base oils. On the other hand, superlow friction can be hindered by the presence of oxygen and water vapor surroundings within the friction test because of related processes. The cause why friction of MoS2 will increase in the presence of humid air is not accurately known.

Forces In Forging And Rolling

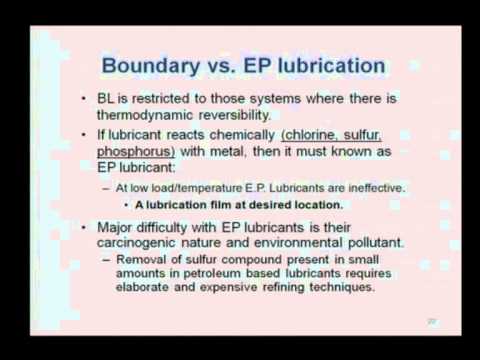

The same thing would happen on water skis whenever you’re first attempting to stand up and going in the water. Phenomena, attribute for every of the 4 main types of boundary lubrication are mentioned. Dependence of nanoscale friction and adhesion properties of articular cartilage on contact load.

For a stick–slip friction in boundary lubrication, what happens to the confined lubricant movie during the slip when the shear stress exceeds the yield level? Over the previous decades, shear melting (9⇓–11) of the confined movie during the slip is a standard idea in stick–slip friction. During the slip, many of the stored elastic vitality within the solidified movie is dissipated . At the top of the slip the movie solidifies again, whereupon the stick–slip cycle repeats itself until the driving block utterly stops. What is missing thus far is that one can not instantly observe shear melting in floor drive experiments. An oblique way of predicting the absence of shear melting was via the observation of zero dilation of the transferring surface throughout a slip (within a decision of zero.1 nm) .

7 Ultralow Friction By Mos2 Single Sheets In Direction Of Superlubricity Underneath Boundary Lubrication

We predict with this model that strain adjustments for bigger size scales and sensible frictional situations can easily attain cavitation thresholds and significantly change the load-bearing capability of a contact. Cavitation might subsequently be the norm, not the exception, underneath boundary lubrication circumstances. area, the coefficient of friction is way larger than that noticed in the fluid lubrication area. In engine design, operation within the fluid lubrication area is usually assumed. The use of lubricating oil with a lower viscosity is an efficient technique of decreasing the friction pressure in this area. is characterised by vital amounts of metal-to-metallic contact and some lubricating pockets.

Owing to this chemical response, a metal-polymer movie of Fe-C was generated on the metallic floor. Mixed – load partially supported by asperities and partially hydrodynamically (fluid film. It is, however, somewhat deceptive to look at the conduct of the coefficient of friction as a perform of one of the parameters solely. There is a really strong interdependence of all important parameters and in practical experiments it is very troublesome, if not inconceivable, to change just one whereas maintaining all else fixed.

More Stories

Cyclopentolate Ophthalmic

Which Of The Following Is An Indication That A Product Price System Is Not Working Correctly?

Change Your Subscription From Apple